Increasingly, robots are replacing humans in food processing plants. One of the advantages is that where robots work, product contamination by personnel is avoided. The problem is that some products, including delicate fruit and vegetables, can be too sensitive for robots to handle.

The German Institute of Food Technologies recognized the problem and took on the challenge of designing technology that handles sensitive products without damaging them. The objective was threefold:

- To develop a novel elastomer (a type of polymer) gripper for the hygienic handling of unpacked food

- To design a robot gripper that grasps sensitive items without destroying them in the process

- To design a gripper that is both flexible and safe for grasping food products of different shapes, sizes and surface finishes.

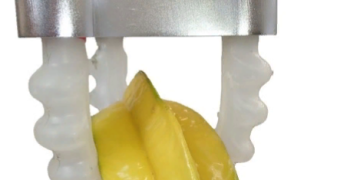

The result is the novel elastomer gripper for hygienic handling of unpacked food by robots.

“The design was inspired by the human hand, which has a very high flexibility with respect to gripping and holding,” said Knut Franke of the institute, who presented the idea at this year’s Anuga FoodTec Fair in Cologne, Germany.

“This is reached by the five fingers, which can be more or less individually moved,” he said. “Additionally, human fingers can follow contours during gripping and holding. The other aspect was the possibility to design it in a very compact manner without mechanical joints. Due to the soft material, gripping force is not as punctual as it is for hard grippers, but distributed over a larger area, reducing peak forces.”

The elastomer-based gripping technology has high potential for handling foods, and it offers several advantages over conventional grippers, including hygiene and flexibility.

The technology is adaptable enough to grip products of different shapes and sizes, and it is easy to manufacture. Since it uses TPE (injection molding), it can be manufactured inexpensively. The gripping system also has a wide range of applications.

Requirements for grippers for foods

While it might seem like fairly simple technology, grippers must meet several requirements in order to be used in food. Today, there are several types of grippers on the market, including mechanical grippers, pneumatic grippers (over and under pressure), electrical grippers and adhesive grippers. Not all are suitable for sensitive foods.

Mechanical grippers, for example, can be challenged by grip force, Franke said. Generally, they use a form or force-locked connection, which can result in product damage. Since vacuum grippers suck liquids into the systems, their use can lead to deposits and potential contamination. As a result, neither is suitable in terms of food safety and quality.

Technologically speaking, grippers used in food processing need to meet a number of requirements, Franke said, including gripping time and length, gripping force and the number of pieces that have to be gripped.

Objects to be gripped are influenced by a number of factors, including shape, mass, surface properties, dryness, stickiness and firmness. Firmness and shape are particularly important in produce processing. Environmental conditions, including temperature and moisture, are also points to consider. Flexibility is also required, especially when handling the natural variability of foods.

“Generally, the principle of elastomer grippers is based on mechanical grippers,” Franke said. “But instead of hard metal or plastic materials, soft elastomers are implemented as gripper material in contact with food surface.”

The second main difference is the gripper function principle.

“Because only the soft fingers are bent by pressure, no joints or similar constructions are required, making these grippers mechanically quite simple,” he said.

Perhaps the most important feature, though, is its compact design, which makes it an ideal choice for use in environments with high hygienic demands.

“The gripper design is fully cleanable because holes and gaps were avoided where product residues can be accumulated,” Franke said.

The design makes it particularly easy to clean, which is a bonus for food processing companies.

The gripper design is the result of a German research project from three different research institutes. The German Institute of Food Technology had the idea for the project, as well as the experience with respect to gripping applications for food. Fraunhover AVV carried out the construction, and the German Institute of Rubber Technology chose the elastomer materials.