There are two elements about the fresh-cut produce line of the future that we can be sure of: raw product will be received and a finished product will depart.

The territory between these entry and exit points, however, may look considerably different than it does today, as produce processors respond to drivers such as economics and food safety, and partner with equipment manufacturers to help them do their jobs better.

“Processors are always looking for higher throughputs, higher yields, sanitary design, quick changeovers and a machine that’s economical,” said Tim O’Brien, vice president of sales at Urschel Laboratories. “Part of what we do as a manufacturer is try to tick all those boxes and come up with a machine that the processors find value in.”

That search for value will lead to changes, both large and small, in food processing facilities.

“Ten years from now, some produce equipment is likely to be much different than it is today,” said John Kadinger, market manager for Key Technology. “With so little automation and so many repetitive tasks, the fresh-cut industry is ready for some big changes.”

One of the biggest changes will involve subtraction rather than addition: there is likely to be far fewer people on the line. If labor costs are driven higher due to developments such as an increase in minimum wage, rising health care costs and a tightening supply of workers food companies might reach a tipping point toward automation.

A decade ago, Tom Gautreaux, national sales director for Maxwell Chase, visited a bakery facility and thought he saw the future: a large production line covering thousands of feet being maintained by only four people.

“Their roles were observation and maintenance,” he said. “If there was a tray jam, they pulled the tray out and the line kept going. They were simply there to see that nothing stopped.”

As someone with 25 years of experience managing processing plants, he said a similar scenario is coming to the produce industry.

“The technology is there. Somebody’s going to put it all together and build an employee-less facility. I think it’s almost doable today, except that nobody’s done the math to say, ‘it’s possible and we can do it.’ I would be shocked if it’s not already in the planning stages,” Gautreaux said.

The move toward automation dovetails with research and development on new methods to enhance food safety. This dual development means that a fresh-cut vegetable line may be one where no human hands ever touch any product that is cut or purged. The first crops to become fully automated would be lettuce, cabbage, onions and other hardy vegetables that can stand up to going through the equipment.

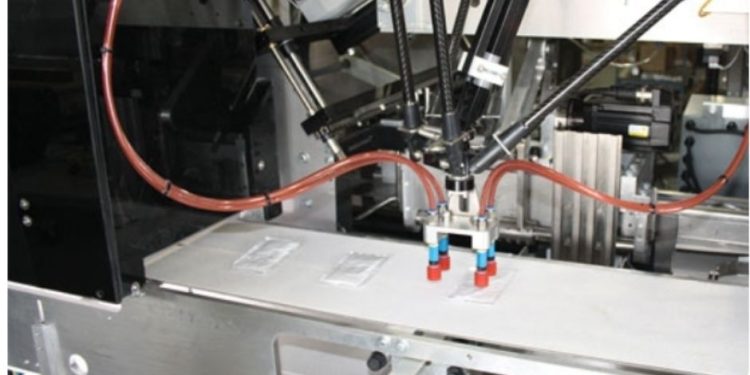

With the possibility of a declining human presence, the potential for automated solutions such as robotics is on the rise. AFA Systems already has robotic case packers at work in food plants, including a green bean processing facility. In one project, an AFA robot and a vision system were paired on a mushroom line to pick out raw product at different orientations and place it into a tray.

“It’s a lot safer because you don’t have a human contact point,” said Eric Langen, AFA’s marketing manager. “It’s very flexible. When you are dealing with different pack patterns in trays, it is very easy to change over the line using a robot.”

Adds Gautreaux: “You can easily sanitize robotics. You can do it every five minutes if you want.”

Economics will motivate more efficient setup and layout of processing lines, as companies think about how the plant equipment works as a whole. The result may be a tighter, more efficient line with fewer transition points, said John Clement, in charge of equipment sales for North Star Engineered Products.

“A lot of plants end up piecing together existing equipment with new equipment. They might have 10 different transition points and five different lines. They can reduce those transition points by just thinking through the whole process better and laying it out better. We might reduce the number of lines and have more flexibility on those lines. Each piece of equipment will be able to be programmed and do a wider range of products.”

One element of the future produce line is almost certain to remain unchanged: the dominance of stainless steel equipment over alternatives such as plastics and composites.

“Stainless or an alloy of that sort is durable and easy to clean, and I’m not sure I see a big move from that going forward,” said Urschel’s O’Brien.

The two major advantages of stainless steel are that it is more easily cleaned and is metal detectable, Clement said.

What might some of the major equipment categories look like in 10 years?

Cutting equipment: The biggest advances in cutting equipment may come in the area of servo-controlled systems, said Clement. These systems can acquire useful data about how the cutting process is actually taking place on a particular product.

Water may also play an increasing role in cutting, whether in hydrocutting (which uses high-pressure water to direct the raw product into an array of knives) or the use of high-pressured jets of water to do the actual cutting.

Sorting: A target for the sorters of the future is their ability to achieve 100 percent inline pathogen inspection, said Kadinger of Key Technology.

“The dream is to essentially take what is now done with a product sample in a lab and expand the test to all the product on the line in real time at full production volume. Of course, to do real-time pathogen detection, we’d need to find new sensors or make improvements to existing sensors to make them more sensitive. We’d also need faster, more powerful computing capabilities to handle all that data. But it’s not unrealistic — similar leaps in technology happen on a regular basis,” he said.

Kadinger images a future where sorting technology will be able to bring an added sensory dimension.

“We can imagine a new digital sorter that has a sense of smell more sensitive than a dog,” he said. “Perhaps it could smell defects and pathogens. Of course, there are many technological hurdles to digitizing smell and that work is in its infancy, but it’s an exciting idea because the opportunity to actually eliminate pathogens in packaged produce is very compelling from a food safety perspective.”

Water systems: Washing systems of the future will see an increasing level of customization, with programmable logic controls and servo motors working together to set up programs that are specific to types of fruits and vegetables.

The same sort of customization can be expected to govern the sanitizers used in the wash water.

“There will be better systems to do real time control of sanitizers and conservation of flow water,” said Clement. “We see that as a huge thing down the road.”

All of these developments may be leading to a future for produce processing plants that will be in step with the overall societal trend toward automation.

“I can see a fully automated plant on the vegetable side very easily. I don’t think you would have to wait until 2025,” Gautreaux said. “You don’t have to have people in the equation. It’s why we have ATM machines and self-scanners in grocery stores. If the cost of employees keeps being driven up, then companies will figure out ways to eliminate employees.”